Prototype Engineering Series: Heat Resin Champagne, Formlabs Printers Compatible

Price:

$90.00

Product Description

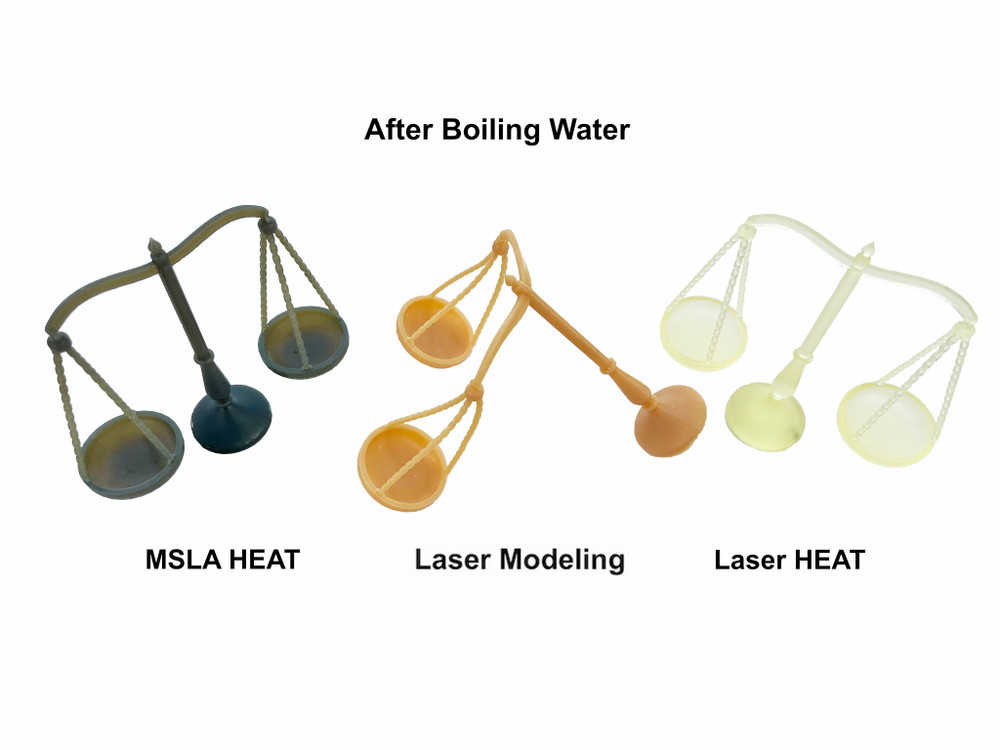

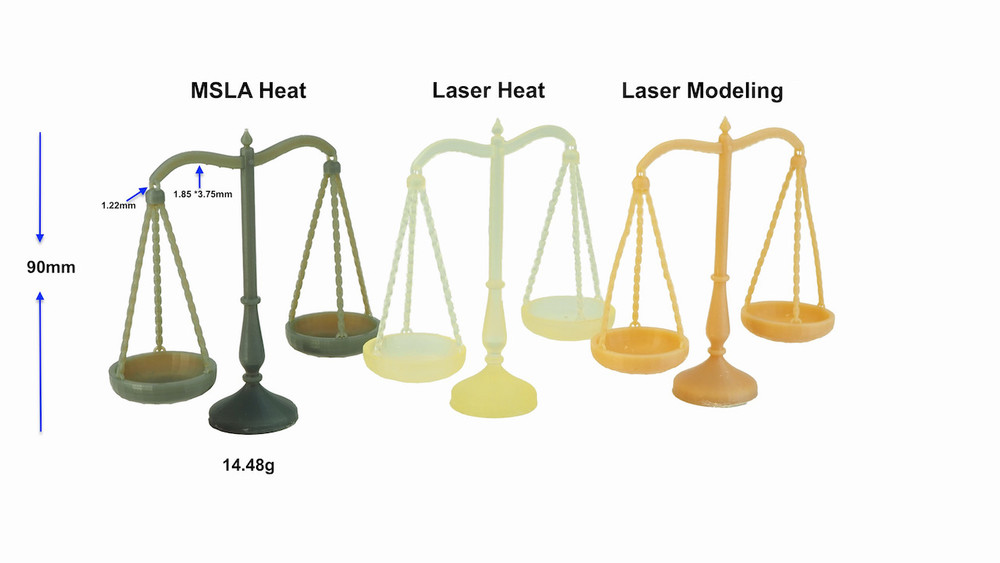

Laser Heat Resin is our most heat resistant resin amongst our Prototype Engineering Series. It has a heat deflection temperature (HDT) of 188oC at 0.45 MPa. It is ideal for prototype parts that will come in contact with high temperature. Laser Heat Resin prints precise models, holds its shapes with high thermal stability.

Product Features

- Calibrated on Formlabs’ Form2 and Form3

- Preform Material Selection: Grey V4

- Formlabs LT VAT is required for Form2

- Print Layer Thickness: 100, 50, 25 microns

- Tensile Strength (65-85 MPa) / Elongation (1-2%)

- Minimum odor

- SKU: PT-HE001CP

- For detailed print instructions, please refer to Printing Tips

Material Properties Table

| Laser-Heat Champagne | PT-HE001CP | |

| Post-curing | FormCure at 60℃/60min |

FormCure at 60℃/60min + oven 160℃/90min |

| Tensile (MPa) | 65 - 80 | 65 - 85 |

| Elongation (%) | 1 - 3 | 1 - 2 |

| Impact (J/m) | 16 - 27 | 23 - 29 |

| Hardness (Shore) | 86 - 88 D | 86 - 88 D |

| Flexure strength (MPa) | 140 - 160 | 150 - 180 |

| Flexure modulus (MPa) | 2550 - 2750 | 2950 - 3100 |

| HDT (℉/℃) | 213.8/101 | 370.4/188 * |

| Viscosity (cP) | 550 - 650 | |

| * FormCure at 80℃/120min + oven 160℃/180min | ||

Product Details

| Color: | Champagne |

|---|---|

| Size: | 1 Liter |

| Material: | Acrylate-based Polymer for 3D Printing |

| Tensile(MPa): | 65 - 80 |

| Elongation(%): | 1 - 3 |

| Impact(J/m): | 16 - 27 |

| Hardness(Shore): | 86 - 88D |

| Flexural Strength(MPa): | 140 - 160 |

| Flexural Modulus(MPa): | 2550 - 2750 |

| HDT(°F/°C): | 213.8/101 |

| Tear Strength(kN/m): | - |

| Compression(%): | - |

| Viscosity (cP): | 550 - 650 |

Material Properties Table

| Laser-Heat Champagne | PT-HE001CP | |

| Post-curing | FormCure at 60℃/60min |

FormCure at 60℃/60min + oven 160℃/90min |

| Tensile (MPa) | 65 - 80 | 65 - 85 |

| Elongation (%) | 1 - 3 | 1 - 2 |

| Impact (J/m) | 16 - 27 | 23 - 29 |

| Hardness (Shore) | 86 - 88 D | 86 - 88 D |

| Flexure strength (MPa) | 140 - 160 | 150 - 180 |

| Flexure modulus (MPa) | 2550 - 2750 | 2950 - 3100 |

| HDT (℉/℃) | 213.8/101 | 370.4/188 * |

| Viscosity (cP) | 550 - 650 | |

| * FormCure at 80℃/120min + oven 160℃/180min | ||