General Casting Tips

Posted by Applylabwork on Sep 9th 2025

Geometric shape/sharp edge hole:

- Feeding system: make sure the joints are well-rounded and fully heated solder joints

- Models position: leave adequate space between models

- Water/powder ratio: decrease water/powder ration to increase investment strength

Rough surface (texture)

- Accelerate temperature ramp

- Investment: follow the instructions of manufacturer, correct amount of water/powder ratio, fully mixed, place flask on stable surface for setting, do not disturb for 2 hours

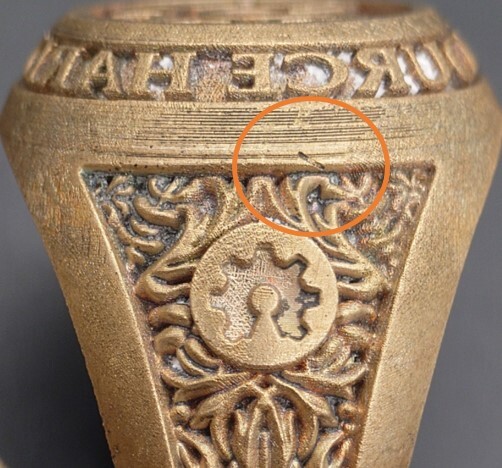

Orange peel: (dense texture, mainly on upper part of model)

- Temperature: decrease the temperature of metal or flask (check the recommend temperature from supplier and adjust according geometry of model and size of flask)

Incomplete filling:

- Temperature: Increase the temperature of metal or flask (check the recommend temperature from supplier and adjust according geometry of model and size of flask)

- Feeding system: increase sprue’s diameter or amount

Small porosity / Dark inclusions:

- Incomplete burnout:

- Extend the maximum temperature hold time for 1 ~ 2 hours

- Turn the flask upside down (pouring cone up) during the last hour of maximum temperature

- Open the door couple times during the maximum temperature

- Accelerate temperature ramp

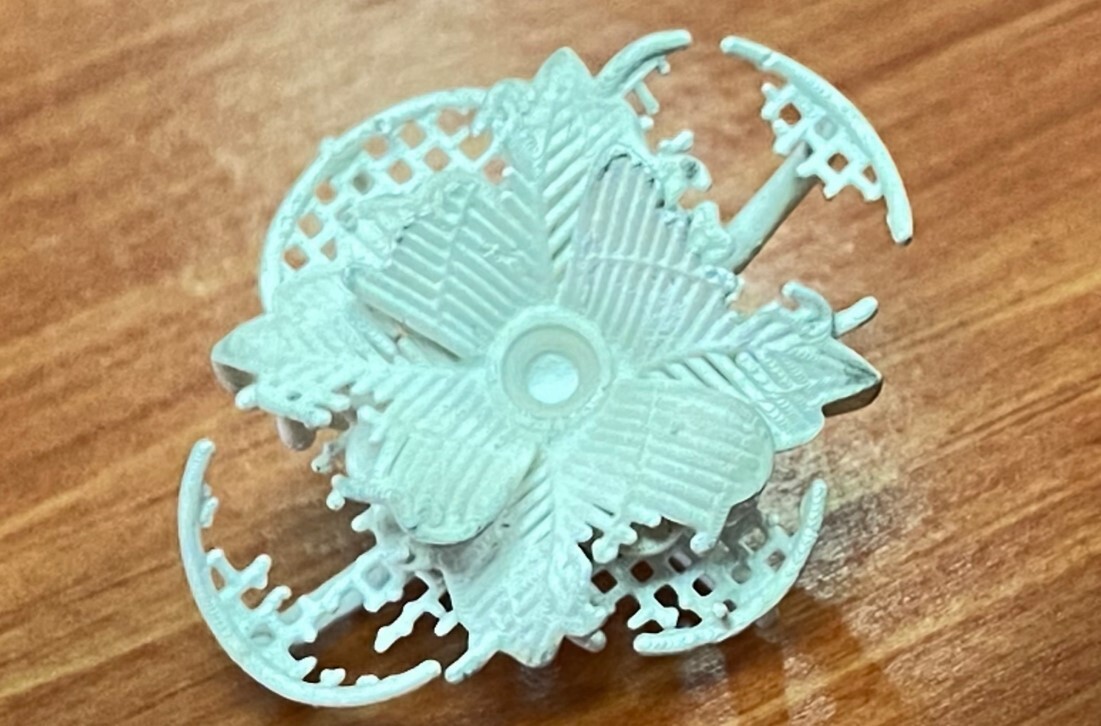

Fin (Flashing):

- Models position: leave adequate space between models, and between models and flask

- Water/powder ratio: decrease water/powder ratio to increase investment strength

- Investment: drying out the investment too long may cause cracking, refer to manufacturer instructions

- Overheat the flask during burnout: refer to manufacturer instructions for the maximum temperature